Polyvinylidene fluoride (PVDF)KF Polymer

Features

<KF Polymer> is a polyvinylidene fluoride (PVDF) resin that Kureha became the first in Japan to commercially produce in 1970. It is a well-balanced, flame-retardant engineering plastic that combines the exceptional properties of fluoropolymers with the moldability of general-purpose resins. KF Polymer is widely used across various fields, including heat resistance, corrosion resistance, and weather resistance applications. Its versatility extends to electronic materials, fishing lines, guitar strings, violin strings, and more. Applications are expanding into advanced technology fields, including binders for lithium-ion battery electrodes and water treatment membranes.

It is possible with KF Polymer.

-

Point 1

Excellent in Processability

KF Polymer is a resin that retains the exceptional properties of fluoropolymers while being adaptable to various molding processes. It supports a wide range of molding methods, including injection molding and extrusion molding.

-

Point 2

High-Purity Resin

KF Polymer does not require additives such as plasticizers or heat stabilizers during processing. As a result, it exhibits significantly lower levels of TOC, metal content, and metal ion elution compared to other general-purpose resins.

-

Point 3

Excellent Chemical Resistance

KF Polymer offers excellent chemical resistance, particularly against acids, making it a suitable material for piping in chemical plants and similar applications.

-

Point 4

Excellent Heat and Weather Resistance

KF Polymer exhibits high heat resistance and stability against ultraviolet rays, making it suitable for use in harsh environments.

-

Point 5

Excellent Mechanical Properties

KF Polymer offers higher mechanical strength compared to other fluoropolymers and excels in wear resistance and impact resistance.

Examples of KF Polymer Applications

KF Polymer is extensively used in essential products that play a crucial role in daily life, such as electric vehicles, smartphones, water treatment membranes, and aircraft.

-

Valves, Fittings, and Piping for Plants -

Water Treatment Membrane -

Aircraft-Related -

Electric Vehicles -

Energy Storage System -

Smartphone/PC

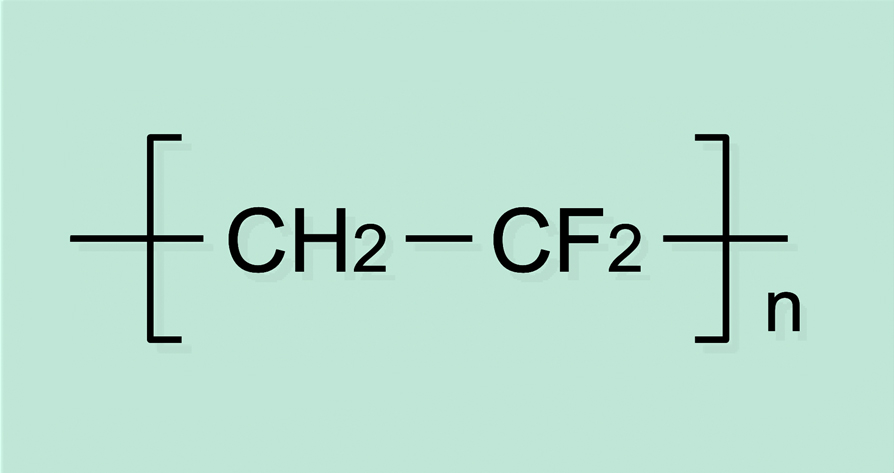

Structure of KF Polymer

PVDF, also known as polyvinylidene fluoride, is a type of fluoropolymer that was first commercially produced by Kureha in Japan in 1970.

Our KF Polymer stands out among commercially available PVDF products due to its low proportion of heterogeneous bonds and limited branching, resulting in high crystallinity and a superior melting point.

Comparison with Other Plastics

KF Polymer combines excellent chemical resistance, heat resistance, and weather resistance with ease of processing. These characteristics make it a preferred choice across a wide range of industries, including chemical engineering, semiconductor manufacturing, medical devices, and construction materials. Unlike general-purpose plastics, KF Polymer can reliably perform even in harsh environments that are challenging for other common plastics.

| Properties (Units) |

PVDF | PTFE | PFA | ETFE | PA6 | Rigid PVC | PP |

|---|---|---|---|---|---|---|---|

| Melting point (℃) |

151-178 | 327 | 310 | 270 | 225 | 75-105 | 170 |

| Tensile strength at yield (MPa) |

30-70 | 20-35 | 25-35 | 38-42 | 70-83 | 42-54 | 17-40 |

| Flexural modulus (GPa) |

0.60-1.99 | 0.53-0.58 | 0.54-0.64 | 0.90-1.20 | 0.70-1.70 | 2.10-3.50 | 1.20-1.70 |

| Dielectric constant (106Hz) |

6.4 | 2.1 | 2.1 | 2.6 | 3.4 | 2.8 | 2.2 |

| Moldability | Melt-moldable | Not Melt-moldable |

Melt-moldable | Melt-moldable | Melt-moldable | Melt-moldable | Melt-moldable |

Fluororesin Handbook, Revised 15th Edition Japan Fluoropolymers Industry Association March 2025

Stable Supply Structure and Quality

Since the start of commerciall production in 1970, KF Polymer has been an indispensable resin across numerous industrial fields for over half a century. Its high quality and reliability are backed by decades of proven performance.

We operate two production facilities: one in Iwaki City, Fukushima Prefecture, Japan, and another in Changshu City, China. By leveraging these two locations, we have established a stable supply structure, ensuring a reliable delivery of products to our customers.

Drawing on our accumulated experience and technological expertise over the years, we provide high-quality products to customers worldwide, building solid trust in the global market.

Cautionary Notes

- The values provided on this website are representative values based on our measurement results, not guaranteed values.

- Please check laws, regulations and product safety before using the product corresponding to purpose and application.

- For safe handling of products, please be sure to check Safety Data Sheet (SDS) in advance. Please use our SDS downloading form to request SDS.

- Information provided on this website is the result obtained based on specific conditions, and we do not guarantee that same result will be obtained by using our materials.

Learn more about KF Polymer

Contact for Inquiries

please contact the site below.

- Product Groups

- Search by Application

-

Advanced Materials

-

Polyphenylene sulfide (PPS)

- Fortron KPS

-

Polyvinylidene fluoride (PVDF)

- KF Polymer

- KF Piezo

-

Carbon Products

- KRECA Carbon Fiber

- BAC

-

Polyglycolic acid (PGA)

- Kuredux

-

Microsphere

- KUREHA Microsphere

-

-

Specialty Chemicals

-

Pharmaceuticals

- KREMEZIN / COVALZIN

-

Agrochemicals

- Metconazole

- Ipconazole

-

Industrial Chemicals

- Inorganic Chemicals

- Organic Chemicals

-

-

Specialty Plastics

-

Household Products

- NEW Krewrap

- Kichinto-San Series

-

Commercial-use food packaging materials

-

Krehalon Film /

Kureha Auto Packer (KAP)

-

Fishing Lines

- SEAGUAR

-

- Construction & Other Services