Thermo expandable microcapsulesKUREHA Microsphere

What is KUREHA Microsphere?

- KUREHA Microsphere is a closed cell foaming agent that is sometimes referred to as thermo expandable microcapsules.

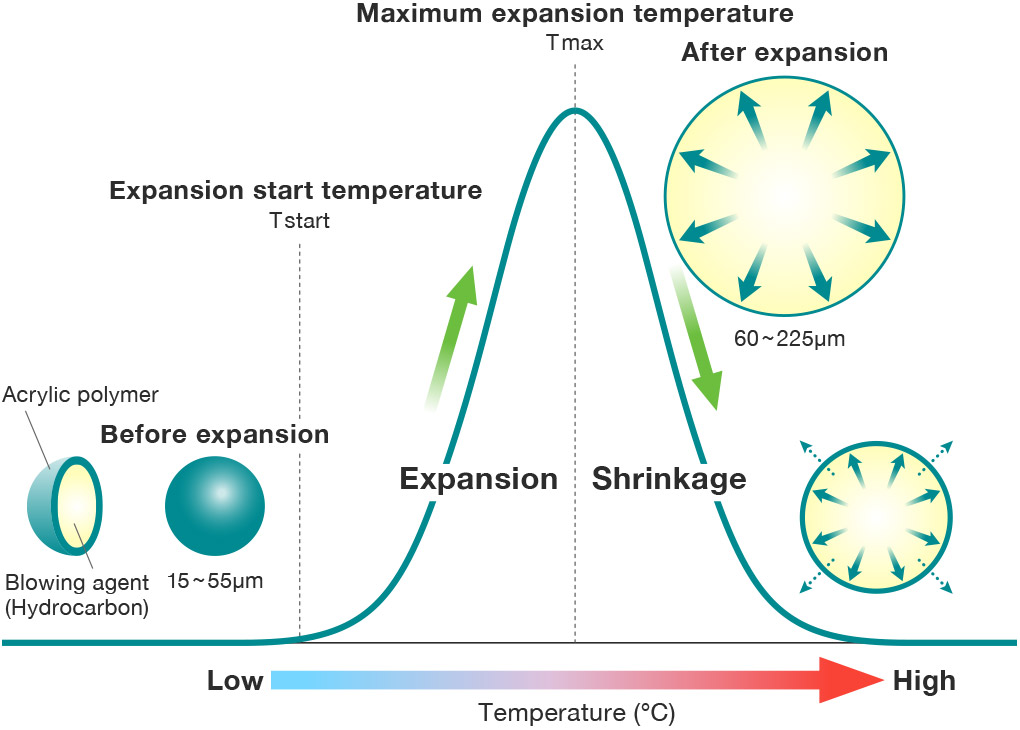

- The hydrocarbon blowing agent resides inside an acrylic shell. When exposed to heat the shell softens while the pressure inside increases, allowing for rapid expansion.

- Expansion starts gradually at the Tstart (activation) and reaches its peak expansion diameter at the Tmax (Maximum expansion temperature).

- Once cooled, the microsphere maintains its shape encapsulating the blowing agent.

- If the microsphere is heated past the recommended Tmax or heated longer than recommended, the blowing agent will gradually escape the shell and the microspheres will lose their shape.

- KUREHA has lineup of microsphere grades suitable for a wide range thermoplastics; including advanced grades that are compatible with higher temperature polymers.

- KUREHA Microsphere is used in wide range of applications including ceiling materials, glass run channels, weather strips, shoe soles, foam ink, wallpaper, heat release tape, artificial leather, and 3D printers.

What are the characteristics of KUREHA Microsphere

- When heated, the volume increases 50 to 170X depending on the grade used.

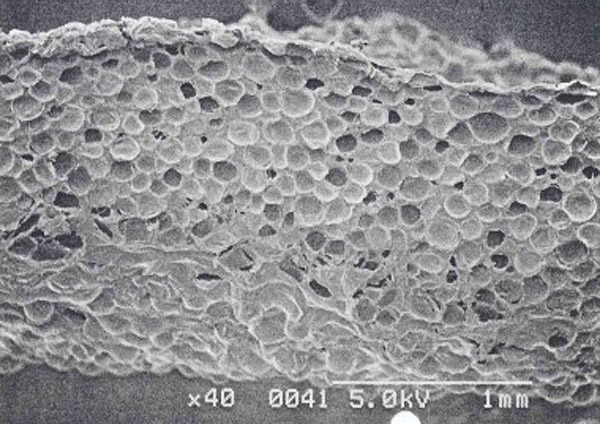

- Expandable microspheres benefits include weight reduction, improved moldability, thermal and sound absorption.

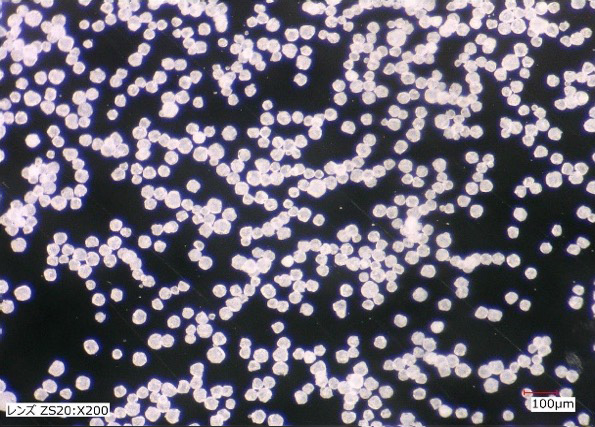

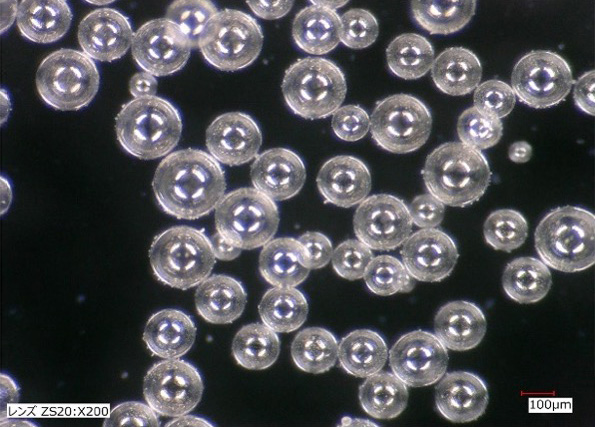

- Microspheres are a precision foaming agent that are characterized by easy control of specific gravity, retention of closed cells, small sphere diameter and uniform distribution.

- Microspheres provide the flexibility to be foamed in resin and within high permeability materials such as fibers and paints.

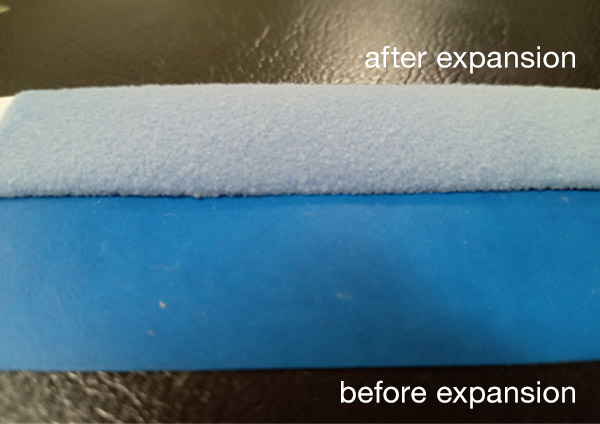

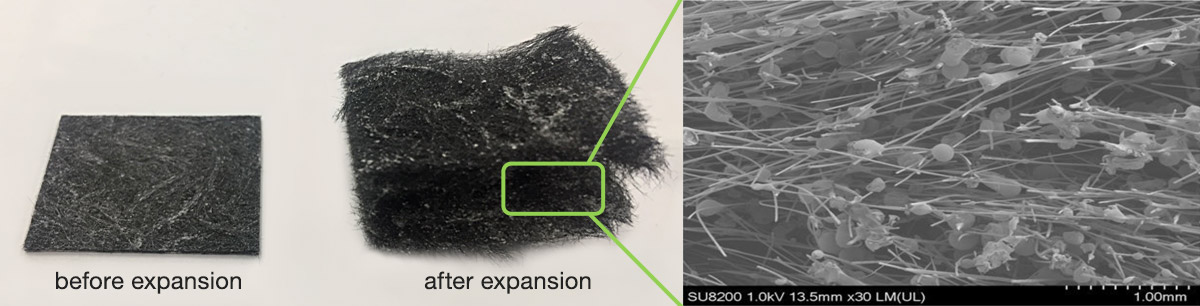

-

Before expansion

-

After expansion

Actual Expansion Images

-

(A) Expansion in resin

-

(B) Expansion in paints

-

(C) Expansion in fibers

Available KUREHA Microsphere grades

| Series | Grade | Average particle size before expansion (μm) |

Average particle size after expansion1) (μm) |

Expansion ratio | Expansion start temperature (Tstart) (℃) |

Maximum expansion temperature (Tmax) (℃) |

|---|---|---|---|---|---|---|

| H | H750 | 15-25 | 60-100 | 50-65 | 120-160 | 160-170 |

| H850 | 30-45 | 155-225 | 125-155 | 120-135 | 170-185 | |

| H880 | 20-35 | 85-135 | 55-70 | 135-160 | 175-185 | |

| S | S1940 | 15-25 | 90-170 | 300-400 | 150-170 | 190-210 |

| S2340 | 15-25 | 70-140 | 100-170 | 170-190 | 230-245 | |

| S2640 | 15-25 | 70-140 | 100-170 | 190-215 | 250-265 | |

| Unique | H1100-S (before heat treatment) |

40-55 | - | - | 170-225 | - |

| H1100-S (after heat treatment) |

145-210 | 45-702) | 145-160 | 175-195 |

1) calculated by expansion ratio

2) after heat treatment (150℃, 5min)

- KUREHA Microsphere grades are classified by "H" and "S" or "Unique" according to processing temperatures and expansion characteristics.

- H series are suitable for expansion at 160℃-190℃

- S series can be used in temperatures above 190 ℃, and are suitable for molding of engineering plastics and elastomers.

- Unique series which have unique expansion characteristics.

Cautionary Notes

- The values provided on this website are representative values based on our measurement results, not guaranteed values.

- Please check laws, regulations and product safety before using the product corresponding to purpose and application.

-

For safe handling of products, please be sure to check Safety Data Sheet (SDS) in advance.

Please use inquiry form to request SDS. - Information provided on this website is the result obtained based on specific conditions, and we do not guarantee that same result will be obtained by using our materials.

Contact for Inquiries

- Product Groups

- Search by Application

-

Advanced Materials

-

Polyphenylene sulfide (PPS)

- Fortron KPS

-

Polyvinylidene fluoride (PVDF)

- KF Polymer

- KF Piezo

-

Carbon Products

- KRECA Carbon Fiber

- BAC

-

Polyglycolic acid (PGA)

- Kuredux

-

Microsphere

- KUREHA Microsphere

-

-

Specialty Chemicals

-

Pharmaceuticals

- KREMEZIN / COVALZIN

-

Agrochemicals

- Metconazole

- Ipconazole

-

Industrial Chemicals

- Inorganic Chemicals

- Organic Chemicals

-

-

Specialty Plastics

-

Household Products

- NEW Krewrap

- Kichinto-San Series

-

Commercial-use food packaging materials

-

Krehalon Film /

Kureha Auto Packer (KAP)

-

Fishing Lines

- SEAGUAR

-

- Construction & Other Services