Thermo expandable microcapsulesKUREHA Microsphere

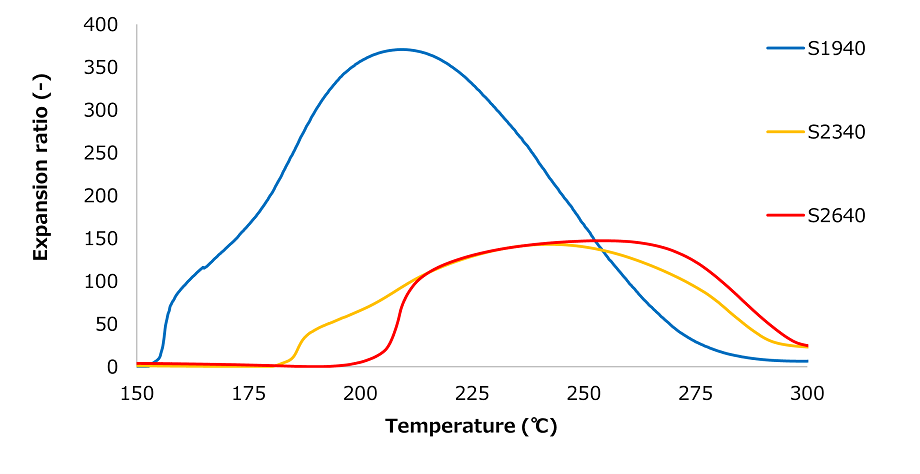

KUREHA Microsphere S series

- S series, can be foamed above 190℃ and are suitable for foam molding of engineered plastics and elastomers.

- When molding by blending with pellets, we recommend masterbatch with excellent dispersibility.

- As a guideline for additive amount of masterbatch, we recommend 2 to 3% for weight reduction and 2% or less for sink mark prevention.

| Series | Grade | Average particle size before expansion (μm) |

Average particle size after expansion (μm) |

Expansion ratio | Expansion start temperature (Tstart) (℃) |

Maximum expansion temperature (Tmax) (℃) |

|---|---|---|---|---|---|---|

| S | S1940 | 15-25 | 90-170 | 300-400 | 150-170 | 190-210 |

| S2340 | 15-25 | 70-140 | 100-170 | 170-190 | 230-245 | |

| S2640 | 15-25 | 70-140 | 100-170 | 190-215 | 250-265 |

Characteristics of each grade

- S1940 : The highest expansion ratio, which is suitable for aggressive density reduction.

- S2340 : It's suitable for applications with molding temperatures from 190 to 230℃. Suitable for expansion of engineered plastics such as PP and ABS.

- S2640 : The highest temperature sphere suitable for process temperatures that range from 230℃ to 260℃ or when avoiding expansion in step-1 of a 2-step molding process.

※ Expansion ratio is calculated by measurement value of thermal mechanical analysis and expanded.

Masterbatch grades

| Masterbatch Grade | Microsphere Grade | Base Polymer | Content (wt%) |

Average particle size (μm) |

Expansion Start Temperature (Tstart) (℃) |

Maximum Expansion Temperature (Tmax) (℃) |

|---|---|---|---|---|---|---|

| MB-S9LC | S1940 | LDPE* | 50 | 15-25 | 150-170 | 190-210 |

| MB-S3LC | S2340 | LDPE* | 50 | 15-25 | 170-190 | 230-245 |

| MB-S6LC | S2640 | LDPE* | 50 | 15-25 | 190-215 | 250-265 |

*LDPE : Low density polyethylene

Movie : Foam molding used KUREHA Microsphere

Extrusion foam molding

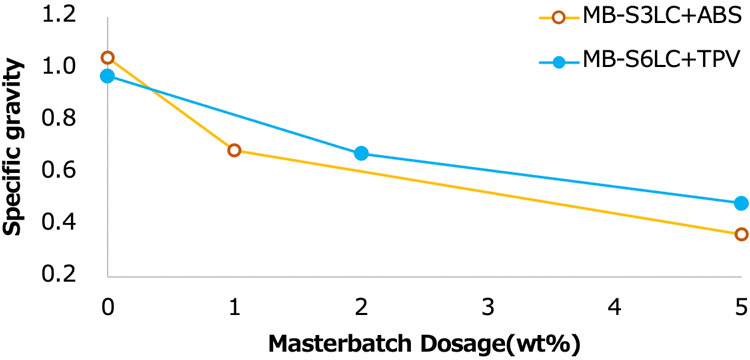

Extrusion foam molding : Example of process conditions

| Masterbatch Grade | Matrix Resin | C1 | C2 | C3 | C4 | Die (℃) |

Resin temperature (℃) |

|---|---|---|---|---|---|---|---|

| MB-S3LC | ABS | 130 | 180 | 230 | 230 | 190 | 210-220 |

| MB-S6LC | TPV | 130 | 150 | 250 | 230 | 190 | 220-230 |

*C1-C4:Cylinder temperature (℃)

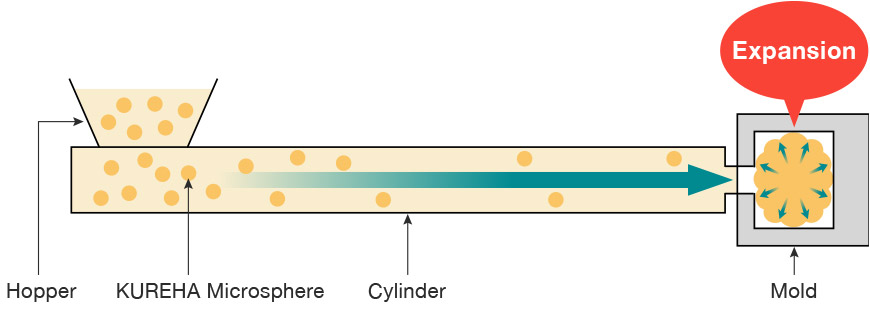

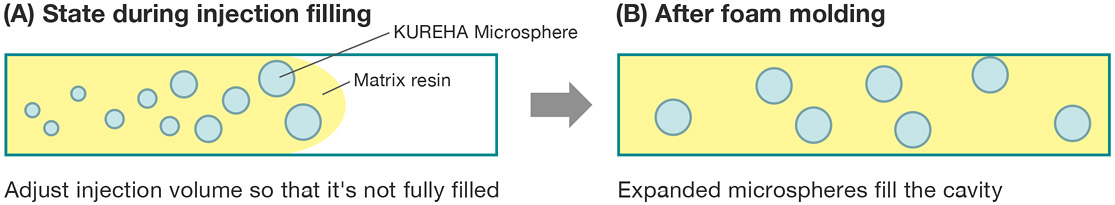

Injection foam molding

- Short shot method used in injection molding.

- Method in which small amount of melt is injected with respect to volume of cavity (Fig. A), and the space is filled by foaming (Fig. B).

- Specific gravity of the product depends on the amount of injected resin.

- KUREHA Microsphere expands when pressure drops (after passing through the nozzle).

- Recommend attachment of shut-off nozzle to prevent from resin dripping.

Injection foam molding : Temperature condition example

| Masterbatch Grade | Matrix resin | C1 | C2 | C3 | C4 | Mold temperature (℃) |

|---|---|---|---|---|---|---|

| MB-S3LC | PP | 160 | 210-230 | 50-80 | ||

| MB-S6LC | PA12 | 200-210 | 230-250 | 30-50 | ||

*C1-C4:Cylinder temperature (℃)

Physical Property

| Masterbatch Grade | - | MB-S3LC | MB-S6LC | ||||

|---|---|---|---|---|---|---|---|

| Matrix resin | - | PP | PA12 | ||||

| Dosage | wt% | 0 | 1 | 3 | 0 | 3 | 6 |

| Density | g/cm3 | 0.88 | 0.73 | 0.67 | 0.99 | 0.85 | 0.78 |

| Expansion ratio | - | 1.0 | 1.2 | 1.3 | 1.0 | 1.2 | 1.3 |

| Light weight ratio | % | 0 | 17 | 23 | 0 | 14 | 21 |

| Flexural Strength (ASTM D790) | MPa | 35 | 27 | 22 | 34 | 27 | 25 |

| Flexural Modulus (ASTM D790) | MPa | 1182 | 1058 | 850 | 885 | 700 | 665 |

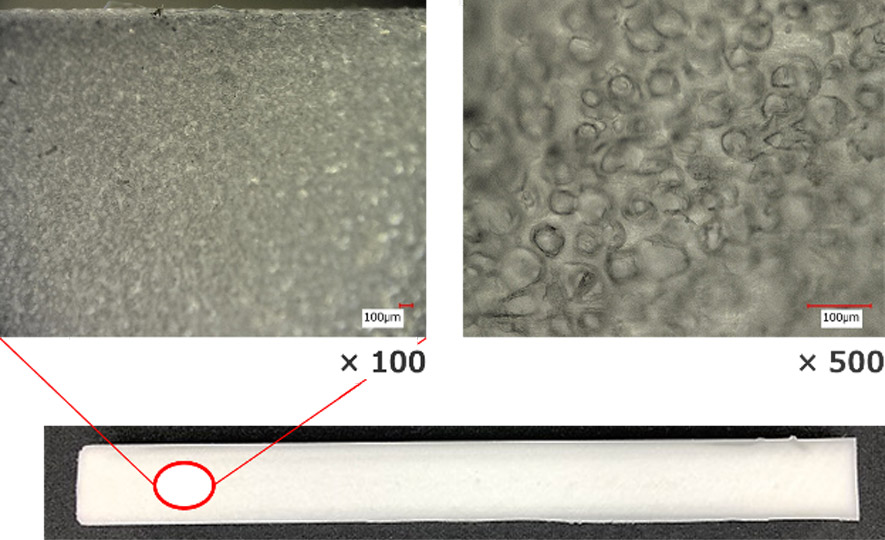

Sectional images of PA12 foams (MB-S6LC : 6 wt%)

- Size : 128 mm x 12.8 mm x 12.8 mm

- Expansion ratio : 1.3 times

- Particle size (Closed cell) : 50 ~ 80 μm

Improved moldability

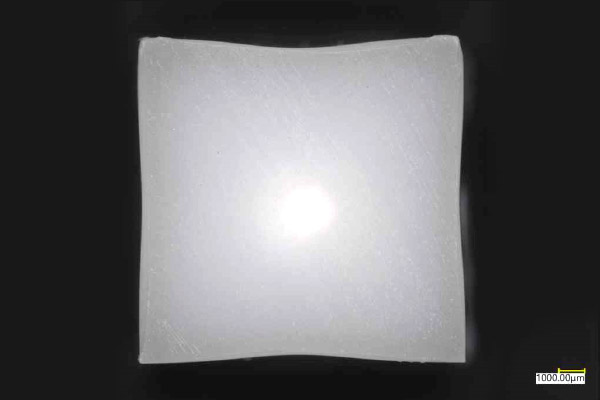

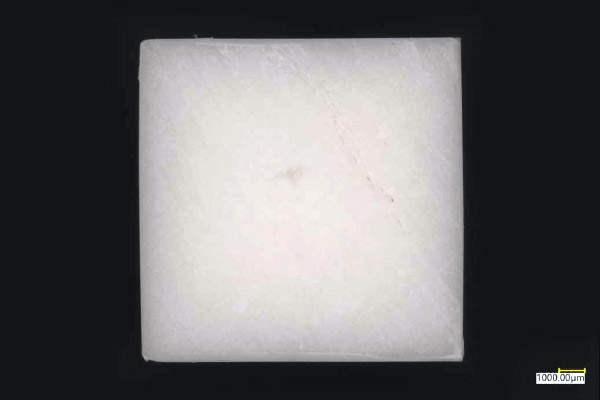

- The use of KUREHA Microsphere improves moldability (prevention of sink marks).

- 2% or less of masterbatched microspheres can improve molding performance.

Photo: Molded piece

-

without KUREHA Microsphere

-

with KUREHA Microsphere

Contact for Inquiries

- Product Groups

- Search by Application

-

Advanced Materials

-

Polyphenylene sulfide (PPS)

- Fortron KPS

-

Polyvinylidene fluoride (PVDF)

- KF Polymer

- KF Piezo

-

Carbon Products

- KRECA Carbon Fiber

- BAC

-

Polyglycolic acid (PGA)

- Kuredux

-

Microsphere

- KUREHA Microsphere

-

-

Specialty Chemicals

-

Pharmaceuticals

- KREMEZIN / COVALZIN

-

Agrochemicals

- Metconazole

- Ipconazole

-

Industrial Chemicals

- Inorganic Chemicals

- Organic Chemicals

-

-

Specialty Plastics

-

Household Products

- NEW Krewrap

- Kichinto-San Series

-

Commercial-use food packaging materials

-

Krehalon Film /

Kureha Auto Packer (KAP)

-

Fishing Lines

- SEAGUAR

-

- Construction & Other Services