Polyvinylidene fluoride (PVDF)KF Polymer

Mechanical Properties

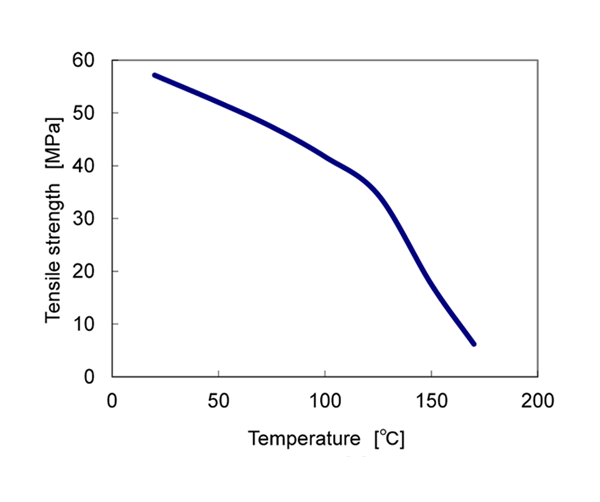

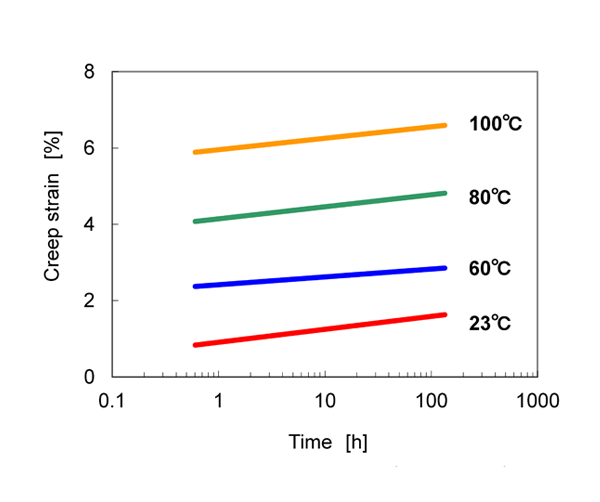

KF Polymer exhibits superior mechanical properties compared to other fluoropolymers due to its high crystallinity. In terms of tensile characteristics, it maintains a strength of over 35 MPa even at 100℃. Additionally, KF Polymer demonstrates exceptionally high creep resistance, which is remarkable for a fluoropolymer.

-

Tensile Properties

(ISO527-2)

Tensile strength (KF Polymer #1000) -

Tensile Creep

(ASTM D2990, 10MPa)

Tensile creep (elongation) (KF Polymer #1000)

-

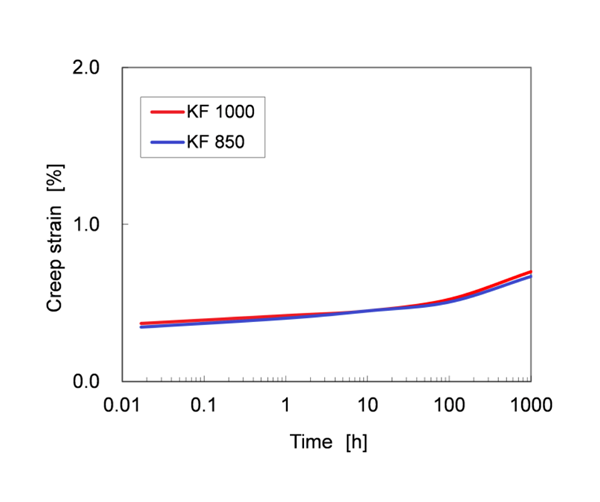

Tensile Creep

(ISO899-1 23℃, 8MPa)

Tensile creep -

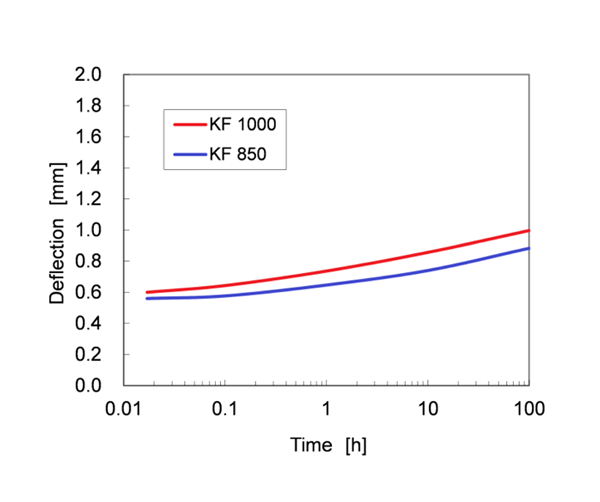

Flexural Creep

(ISO899-2 23℃, 8MPa)

Flexural creep

Thermal Properties

The melting point of KF Polymer is approximately 175℃ for homopolymers, with a glass transition temperature of around -35℃. This allows it to operate reliably over a temperature range of approximately -30℃ to 150℃ for extended periods. Additionally, KF Polymer without any additives has flame retardant meeting UL94V-0 or equivalent.

Chemical Properties

KF Polymer possesses excellent chemical resistance. With the exception of certain strong acids and strong bases, it demonstrates high resistance to a wide range of acids, bases, oxidizing agents, reducing agents, and various organic solvents. This characteristic allows it to maintain stable performance even in harsh chemical environments where generic plastics would fail. Additionally, its ability to retain its physical properties over extended periods is highly valued.

after ozone exposure

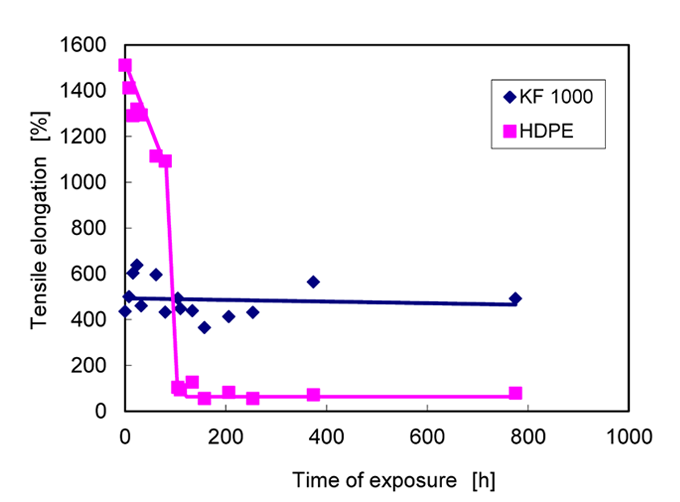

Ozone Resistance Properties

Ozone resistance properties of KF Polymer are very good compared with High Density Polyethylene (HDPE).

(Exposure conditions; 1.0-1.2 % Ozone,

Room temperature

Sample thickness=0.15 mm,

Sample width=5 mm,

Testing length=20 mm,

Tensile speed=1.0 mm/min.)

Elution of Impurities

KF Polymer does not require additives such as plasticizers or heat stabilizers during processing, resulting in significantly lower levels of eluted substances compared to other general-purpose resins. Furthermore, its exceptionally high purity makes it suitable for applications such as piping for ultrapure water systems.

Elution of total organic carbon (TOC) (95℃ hot water, 6 days)

| Homopolymer | Modified polymer | |||

|---|---|---|---|---|

| #850 | #1000 | #1100 | #2950 | |

| TOC (µg/g) |

1.6-2.3 | 1.6-2.2 | 1.6-2.2 | 1.2-2.8 |

*Specimen form: pellets

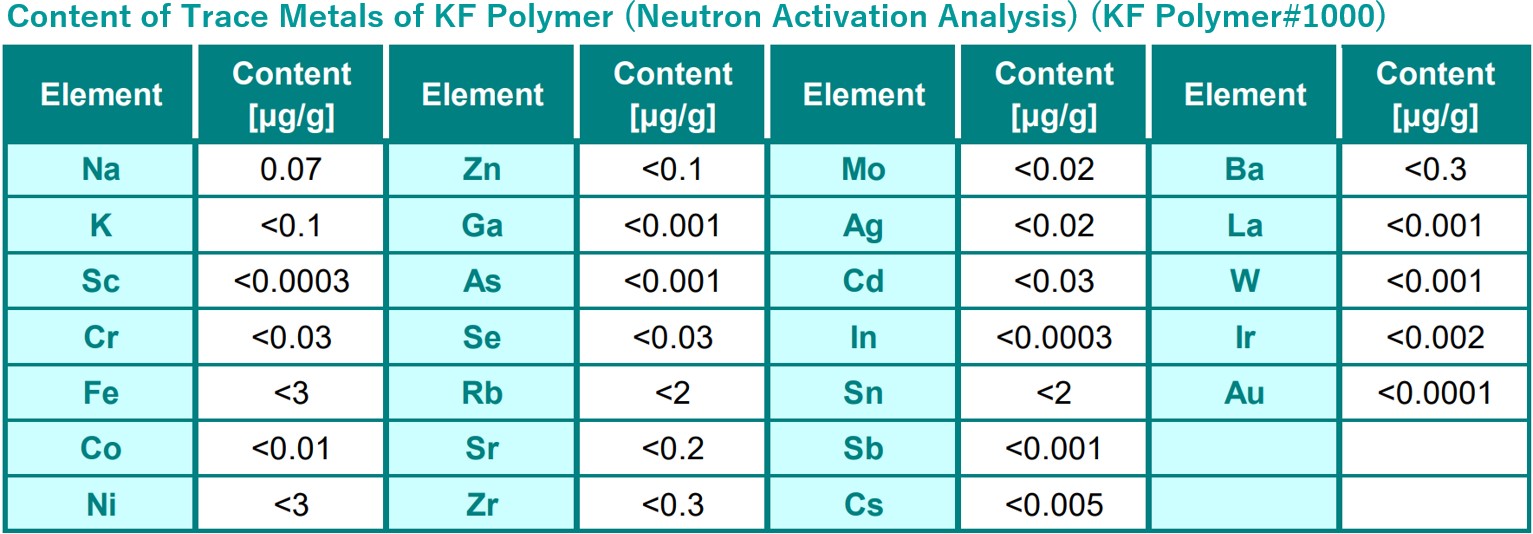

Content of Trace Metals

KF Polymer contains minimal metal content, making it suitable for high-purity applications where metal elution is undesirable.

Weatherability

KF Polymer exhibits excellent resistance to natural environmental factors such as ultraviolet rays, humidity, and temperature. Under standard conditions, it is suitable for prolonged outdoor use.

-

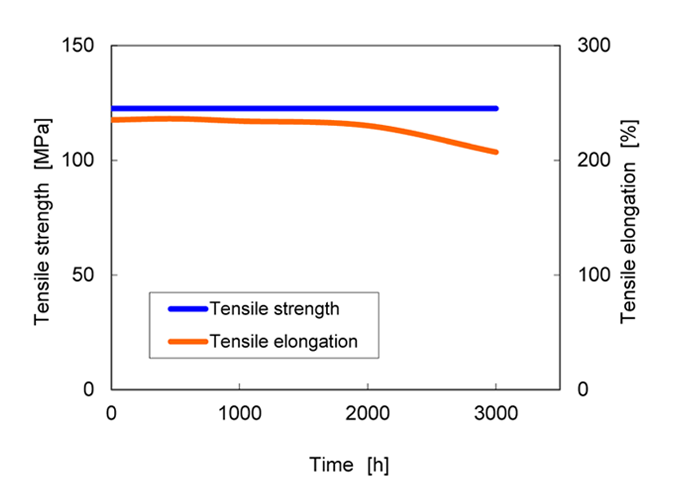

Weatherability of KF Polymer (Mechanical Properties)

KF Polymer has excellent weatherability. Therefore, it has been used as a transparent antifouling film material for the outdoors.

Weatherability test - tensile strength and elongation Exposure condition: Weatherometer, Carbon-arc lamps,

Cycle: 12min spray / 60min stop, 63±3℃, 50-60 %RH

Sample: KF Polymer #1000, Film thickness: 35 μm -

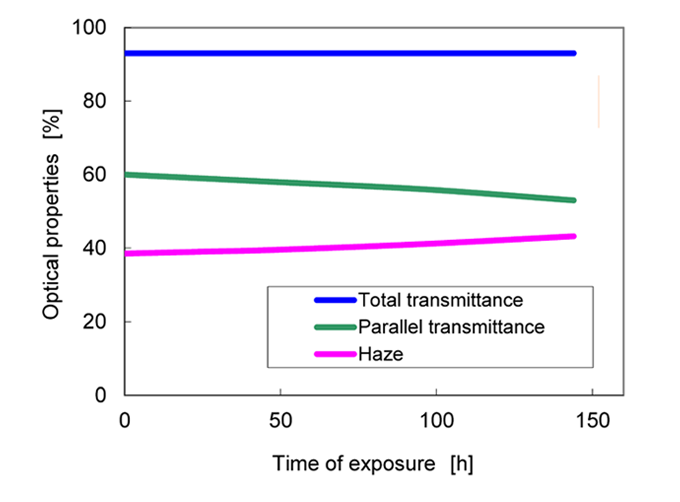

Weatherability of KF Polymer (Optical Properties)

KF polymer maintains stable optical properties under outdoor exposure, making it suitable for use in a wide range of cover films.

Weatherability test - optical properties Exposure condition: Super UV tester, Fluorescent UV lamps,

83 mW/cm2, Black panel temp.: 63℃, 60 %RH

Sample: KF Polymer #1000, Film thickness: 100μm

Storage

To maintain product performance, store in an indoor environment where condensation does not occur and avoid direct sunlight.

- For details on handling the raw material, please refer to the Safety Data Sheet (SDS).

Learn more about KF Polymer

Contact for Inquiries

please contact the site below.

- Product Groups

- Search by Application

-

Advanced Materials

-

Polyphenylene sulfide (PPS)

- Fortron KPS

-

Polyvinylidene fluoride (PVDF)

- KF Polymer

- KF Piezo

-

Carbon Products

- KRECA Carbon Fiber

- BAC

-

Polyglycolic acid (PGA)

- Kuredux

-

Microsphere

- KUREHA Microsphere

-

-

Specialty Chemicals

-

Pharmaceuticals

- KREMEZIN / COVALZIN

-

Agrochemicals

- Metconazole

- Ipconazole

-

Industrial Chemicals

- Inorganic Chemicals

- Organic Chemicals

-

-

Specialty Plastics

-

Household Products

- NEW Krewrap

- Kichinto-San Series

-

Commercial-use food packaging materials

-

Krehalon Film /

Kureha Auto Packer (KAP)

-

Fishing Lines

- SEAGUAR

-

- Construction & Other Services