Waste and Recycling

With conservation of resources and reduction of our impacts on the environment in mind, we make efforts to reduce our generation of waste and promote recycling to reduce the final disposal volume of waste generated from production activities at our business sites. We also work to properly manage and dispose of waste in compliance with laws and regulations, and reliably fulfill our recycling obligations under the Containers and Packaging Recycling Law.

Goals and Vision

- Reduce waste and promote recycling.

Fiscal Year 2022 Plan

- Reduce the amount of waste generated and disposed of through stable operations, reducing volume, recycling, etc.

- Ensure the fulfillment of legal responsibility for waste storage and disposal.

- Systematic on-site confirmation of proper disposal at companies entrusted with waste.

Fiscal 2022 Performance and Outcomes

- Curbed unplanned waste generation.

- Continued proper management efforts when outsourcing waste processing.

- Conducted audits (13 companies), on-site checks (1 company), and documented checks of the status of management (15 companies) at waste contractors, confirming the absence of problems at any contractors.

Reduction of Waste Generated

Kureha is working to reduce the volume of waste sent to final disposal (landfill) by curbing the volume of and by actively recycling waste discharged by our production activities. In fiscal 2023, we set the following waste reduction targets to be achieved by fiscal 2030.

Kureha's Zero Waste Emission Rate* Targets

- Achieve a zero waste emission rate* of 1.5% by fiscal 2025

- Maintain a zero waste emission rate of 1.5% in fiscal 2030

- *Definition of zero waste emission rate: volume of industrial waste sent to final disposal (landfill) ÷ total volume generated (excluding volume from construction work).

At the Iwaki Factory, coal ash emitted from the on-site coal-fired power plant accounts for the majority of waste. We are working to enhance the recycling rate by outsourcing this waste to recycling contractors for use as a cement material.

We are also making efforts to curb the generation of waste at our production sites through means including improvements to production efficiency. Furthermore, we are striving to reduce the volume of waste sent to final disposal (landfill) by examining waste disposal methods and promoting recycling. In fiscal 2021, our volume of industrial waste generated and volume sent to final disposal (landfill) increased, due in part to the one-time disposal of surplus construction soil. However, the volume sent to final disposal (landfill) decreased in fiscal 2022 through efforts to boost our recycling rate. Our Plastics Processing Factory, too, actively tackles the reduction of production losses, the development of products that reuse production losses, and the recycling of resources.

These activities contributed to a zero waste emission rate of 9.0% in fiscal 2022. Looking ahead, we will continue efforts toward further reduction of the volume of waste generated and sent to final disposal (landfill) through stable plant operation, curbing of waste generation through the development of high-efficiency processes, and the introduction of new recycling technologies.

The promotion of resource recycling and the reduction of volume of waste sent to final disposal (landfill) are material issues for our Company. We will reduce wastes and engage in recycling to achieve our fiscal 2025 target of a 1.5% zero waste emission rate and will contribute to the reduction of impacts on the environment.

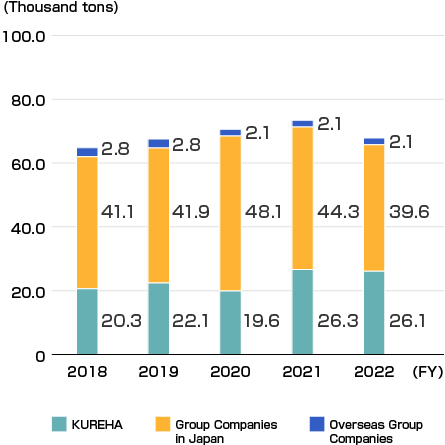

Waste Generation (Kureha Group)

- -The volume of waste generated by domestic Group companies includes the amount generated by Kureha Ecology Management's industrial waste treatment and waste from construction work at Kureha Construction.

Recycling Rates1 (Kureha Group)

| FY2018 | FY2019 | FY2020 | FY2021 | FY2022 | |

|---|---|---|---|---|---|

| Kureha | 57.6 | 58.6 | 58.7 | 57.2 | 70.0 |

| Group Companies in Japan | 33.7 | 36.3 | 43.2 | 44.8 | 45.6 |

| Overseas Group Companies2 | 57.6 | 14.9 | 15.1 | 18.7 | 66.2 |

- 1 Recycling rate = Amount recycled (including heat recovery) / Amount of waste generated x 100

- 2 We have revised the calculation method for fiscal 2022 to include heat recovery and recycling.

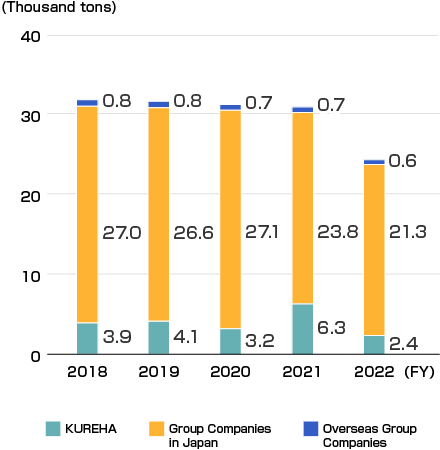

Volume of Waste Sent to Final Disposal (Landfill) (Kureha Group)

Proper Management of Wastes

Kureha complies with waste-related laws and regulations and works to properly manage waste. We have adopted the use of electronic manifests for use in waste management at all of our business sites.

Our Iwaki Factory employs an ISO 14001-based management system to properly manage waste storage areas and to check storage conditions. We share information on wastes with managers in charge of all waste-emitting departments through environmental committee report materials and other means to raise awareness among managers. We also conduct on-site checks of waste disposal contractors in line with our annual plans. In fiscal 2022, we conducted an on-site check of one contractor in the city. Due to the COVID-19 pandemic, we conducted documentation-based checks of the status of management at 15 contractors outside the city, confirming the absence of problems with any of them.

Our Plastics Processing Factory conducts monitoring of storage conditions and proper management at waste storage areas based on its own triple-system internal regulations (a management system that integrates quality, occupational safety and health, and the environment). The factory outsources the transport, intermediate treatment, and final disposal of wastes to many contractors, and systematically conducts on-site checks to confirm the status of proper treatment by the contractors. The factory also visits new contractors to confirm that discharged wastes undergo proper treatment while pointing out areas for improvement. The factory also conducts regular checks of the storage status of recycling contractors. In fiscal 2022, the factory conducted audits of 10 contractors and three new contractors, confirming the absence of problems with any of them.

We will continue such efforts directed at the proper management of waste.

Awareness of Efforts on Marine Plastic Pollution and Recycling of Plastics

As a company, we must reduce our impact on the natural environment as much as possible for the development of a sustainable society. As a Group that manufactures and sells plastic products and materials, we have a responsibility to work for environmentally friendly production activities as we continue to provide technology-based products and services that target various environmental issues, such as global warming, water problems, marine plastic pollution, and resource recycling. The Kureha Group will continue to protect our rich natural environment by promoting environmentally-conscious initiatives at every stage of the supply chain, including R&D, manufacturing, sales, collection, and disposal.

Here, we would like to introduce our Group's resource recycling initiatives that address issues including marine plastic pollution.

Kureha Group's Environmental Awareness and Initiatives

Basic Awareness

As a plastics manufacturer, the Kureha Group has the following basic awareness of environmental issues:

Plastics have a wide variety of uses and, when their unique characteristics are effectively utilized, they contribute to such things as increasing energy efficiency and reducing food loss.

However, since their recycling rate is still quite low and because they are improperly disposed of, they end up as marine plastic waste, becoming a huge factor in environmental pollution.

We at the Kureha Group believe it is necessary to participate in the global effort toward:

1. Development of a plastic recycling system, and

2. Prevention of pollution by marine plastic waste.

Group Initiatives

In order to fulfill our corporate social responsibility, the Kureha Group is taking the following measures against these issues:

Promoting the three R's (reduce, reuse, and recycle)

- Reducing losses and examining ways to reuse and recycle in the manufacturing process

- Promoting environmental businesses such as recycling and heat recovery technologies

Responding in product design and development

- Designing products which reduce household waste and simplify the task of garbage separation

- Reducing raw materials used while maintaining functionality

- Developing biodegradable plastic products such as PGA degradable plugs

Promoting efforts to prevent littering on land and into the ocean

- Raising consumer awareness through proper labeling of product disposal

- Preventing plastic waste leaking into water bodies during the manufacturing process

- Collaborating with local and regional governments to eradicate littering and illegal dumping

- Promoting cleanup efforts around each business site and neighboring areas

We will continue to make sincere efforts, together with industry Groups, to fulfill our corporate responsibility to preserve the natural environment according to the policies and plans of the international community and the Japanese government.

- -PGA "Kuredux" is certified as a biodegradable plastic in Europe and Japan.

Plastic Resource Circulation Act

As a business that generates industrial wastes including those from products made with plastic, we will actively work to reduce and recycle wastes while disclosing related information, doing so under the Plastic Resource Circulation Act* that came into force in April 2022.

- *Plastic Resource Circulation Act: A law involving the promotion of resource recycling related to plastics

Containers and Packaging Recycling Law

Kureha steadily carries out the recycling obligations it bears under the Containers and Packaging Recycling Law.

Since fiscal 2002, we have outsourced recycling, mainly of paper and plastic containers and packaging, under contract to the Japan Containers and Packaging Recycling Association, a designated corporation and a public interest incorporated foundation.

Industrial Waste Final Disposal Sites: Maintenance Information

- Sustainability

- Message from the President

- Kureha Group's Sustainability

- Material Issues

- Environmental Report

- Social Report

- Governance Report

- Kureha Group's Sustainable Product Development

- Environmentally and Socially Friendly Products

- GRI Standards Content Index/Comparison with ISO 26000

- ESG Data Collection

- Sustainability Report Archive

- Group Company Initiatives

- External Recognition

- Sustainability Site Editing Policy and Contents of the Report