Occupational Safety and Health

Safety is the most important foundation of the manufacturing industry. Kureha conducts workplace inspections and internal audits under the supervision of the Health Committee and Safety and Health Committee as required by laws and regulations, as well as the departments in charge of each business site, and is seeking to expand safety activities (the 5S system, point and call, hazard prediction, risk assessment, etc.) with the aim of eliminating all personal injury accidents. We are also committed to educating the people who support these activities. In addition, we share information on occupational safety and health with other Group companies through the Kureha Group RC Council.

- Occupational Safety and Health Management System

- Occupational Safety and Health Activities

- Safety and Health Committee and Health Committee

- Occupational Safety and Health Awareness Programs

- Chemical Substance Risk Assessment in the Workplace

- Skills Training Center

- Eliminating Logistics Accidents

- Declaration of Voluntary Action to Support the White Logistics Movement

- RC TOPICS: Kureha Construction's Mizuhiro Masaki received the Green Cross Award from the Japan Industrial Safety & Health Association in recognition of his occupational safety and health efforts

Goals and Vision

- Eliminate serious personal injury accidents.

Fiscal Year 2022 Plan

- Maintain and improve the root cause analysis capabilities.

- Prevent accidents by enhancing the Skills Training Center functions and expanding the number of trainees.

- Improve safety levels through cross-checking and enhanced cooperation among Group companies in their activities.

Fiscal 2022 Performance and Outcomes

- Lost-time accidents: 6, non-lost-time accidents: 13 (including two business sites and Group companies within each site).

- Conducted why-why analysis training sessions for managers and supervisors to improve their root cause analysis and solution developing capabilities.

- Implemented thorough on-site checks and confirmed correction policies during factory manager patrols (18 times in total at two business sites).

- Disseminated information on priority items for scheduled maintenance at scheduled maintenance and safety meetings.

- Completed safety training for partner company supervisors, and expanded safety training to include partner company employees.

Occupational Safety and Health Management System

Kureha and all Group companies prioritize the safety and health of all our workers and are actively promoting the introduction of an occupational safety and health management system in line with our business activities with the goal of zero occupational accidents.

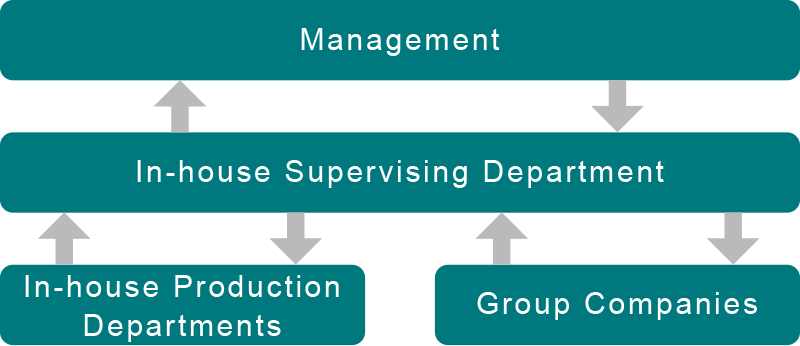

Occupational Safety and Health Activities

The Kureha Group aims to eliminate personal injuries and equipment-related accidents at all of its business sites, under the motto "Safety as a first priority." To achieve this goal, all employees are instilled with the importance of strictly avoiding accidents, going home safely, thoroughly following set rules, never taking shortcuts and never breaking promises. To ensure continued safety, in addition to renewing facilities and equipment, Group companies are collaborating to implement safety promotion activities and establish a centralized management system for emergency communication in the event of an accident. Through these efforts, we will continue to strengthen the safety system of the entire Group.

Safety and Health Committee and Health Committee

In accordance with the Industrial Safety and Health Act, Kureha has established a Health Committee at our head office and a Safety and Health Committee at each business site, where labor and management work together to promote initiatives that meet the needs of each business site. The minutes of the monthly committee meetings are posted on our internal online information system in order to share the details of reports on health management, infection control, improvement of the work environment, and accident prevention with our employees. In addition, information on accident cases is shared in detail via e-mail and our online information system as soon as possible, as well as on a database, and efforts are made to ensure that all employees are fully aware of the situation in order to prevent recurrence.

Occupational Safety and Health Awareness Programs

In conjunction with Japan's National Safety Week, which is observed in July every year, executives at the Iwaki Factory conduct safety patrols and conventions to check the status of safety measures and raise safety awareness.

In July 2022, the General Manager of the Manufacturing & Technology Division and General Manager of the Iwaki Factory, Manufacturing & Technology Division conducted safety patrols together with factory executives to check the safety measures of each department and held a safety convention to commend departments that achieved zero personal injury and equipment-related accidents. In addition, a lecturer from outside Kureha was invited to give a speech titled Aim to Create a Safety-First Workplace: Practical Actions to Prevent Accidents and Missteps. The speech was livestreamed to the Ibaraki and Hyogo sites of our Plastics Processing Factory.

A lecturer from outside Kureha conducted training on why-why analysis in January 2023 at the Iwaki Factory, and again in February at the Plastics Processing Factory with the aim of maintaining and improving root cause analysis capabilities (target participants: managers and on-site supervisors at the Iwaki Factory and managers at the Plastics Processing Factory). This training consisted of two parts aiming to further improve their analytical skills. The first part was a structured introduction to the basics of why-why analysis, and in the second part participants put what they learned into practice by doing why-why analysis on past accidents to logically find their root causes.

For Japan's National Occupational Health Week, which is observed every October, each factory conducts activities and lectures on sanitation and health. In October 2022, the Iwaki Factory invited a lecturer from outside Kureha to give a special speech on safety and health titled Healthy Longevity Starts with Your Mouth—Preventing Lifestyle-related Diseases and Dementia through Oral Care. In October 2022, the Ibaraki and Hyogo sites of the Plastics Processing Factory conducted special lectures on occupational health titled Prevention of Stress-Related Diseases via recorded stream.

Training session (Iwaki Factory)

Chemical Substance Risk Assessment in the Workplace

Due to the revisions of the Ordinance on Industrial Safety and Health in 2022 and other revisions, information communication through SDS (Safety Data Sheet)1 and labeling of chemical substances, risk assessments, and measures to prevent exposure to workers will be shifted to autonomous management starting in fiscal 2023. In addition, work records will be a requirement as the number of substances considered carcinogenic has increased significantly.

In order to respond to these revisions, education on their content was conducted within the Kureha Group. The Kureha Group will continue to implement various initiatives in all departments that handle chemical substances. In addition to BIGDr.Worker2, which we have been using as a risk assessment tool, we have adopted CREATE-SIMPLE3 to enhance risk assessment in terms of both hazard and toxicity. For operations identified as high-risk, risk reduction measures are taken under the leadership of both the Chemical Substance Manager and the Protective Equipment Manager.

In fiscal 2022, there were no cases of ailments or ill health caused by hazardous chemicals.

- 1.Documents describing hazard and toxicity information of chemical substances.

- 2.A worker risk assessment support tool developed by the Japan Chemical Industry Association (JCIA) that can be used to conduct risk assessments in accordance with the Industrial Safety and Health Act.

- 3.A simple chemical risk assessment tool developed by the Ministry of Health, Labour and Welfare for all types of industries.

Skills Training Center

At the Iwaki Factory, we are working together with Group companies to raise awareness about disaster prevention and occupational safety and health, and to eradicate occupational accidents. As part of that effort, we opened the Skills Training Center in November 2005 where employees learn to work with a heightened sense of safety by experiencing simulations of dangers that may occur during work. As of March 2023, a total of approximately 45,000 trainees have participated in the center since its opening.

In fiscal 2022, as part of our efforts to eliminate construction and maintenance work-related accidents at the Iwaki Factory, we conducted a safety course for employees of construction and maintenance partner companies working at the Iwaki Factory, with approximately 310 people having taken the course by March 31, 2023.

Skills Training Center Programs

Safety Simulation Programs

- Clothing check

- Working at heights hazard simulation

- Rotating parts hazard simulation

- Slinging work hazard simulation

- Fire and explosion simulation

(flammable liquid fire, dust explosion) - Electrical hazard simulation

(electrical fire, electric shock) - First-aid simulation

- Emergency lifesaving simulation

(CPR, AED) - Hazard prediction training (short-time training)

- Point and call simulation

- Steam trap hazard simulation

- Dangerous liquid exposure simulation

- Decompression and liquid expansion hazard simulation

Responding to Revisions to the Industrial Safety and Health Act

Revisions to the Industrial Safety and Health Act have made it mandatory to use fall arrest equipment that meet performance requirements when working at heights, and special training is also required for workers who use full-harness fall arrest equipment (4.5 classroom hours and 1.5 practice hours by law). The Skills Training Center is equipped with training tools and related equipment and has been conducting special training courses since October 2019. By the end of March 2023, a total of approximately 640 employees have undertaken special training here.

Eliminating Logistics Accidents

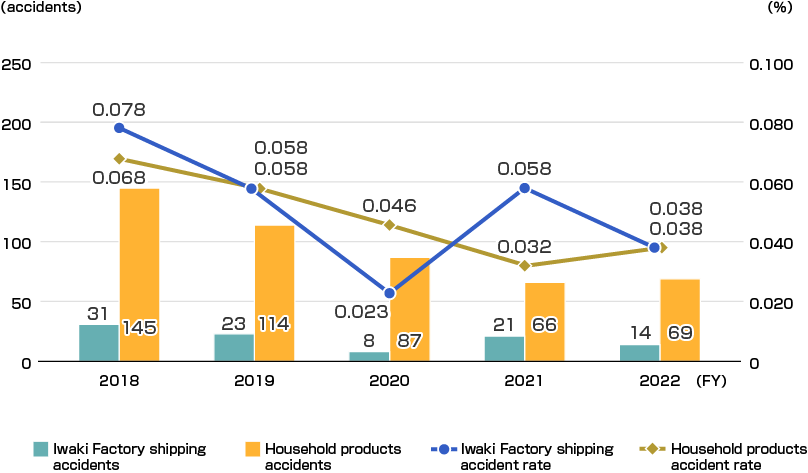

Kureha is working to eradicate all logistics accidents that occur during transportation of our products.

As for products shipped from the Iwaki Factory, Kureha Unyu Co., Ltd., which handles the shipments, collaborates with related in-house departments to prevent accidents. With continuous safety training of Kureha Unyu crew members, strengthening undercarriage inspections, and various other measures, we are working to prevent leaks and other such things that could lead to serious accidents, and also working to reduce delivery errors and all other logistics accidents.

For household wrapping products, such as NEW Krewrap, shipped from our Plastics Processing Factory, we will continue to implement various countermeasures against logistics accidents, such as thorough education of and guidance to our transportation partners and reflecting the results of accident factor analysis in our education plans.

■Logistics Accidents

Declaration of Voluntary Action to Support the White Logistics Movement

Kureha endorses the White Logistics Movement advocated by the Ministry of Land, Infrastructure, Transport and Tourism, the Ministry of Economy, Trade and Industry, and the Ministry of Agriculture, Forestry and Fisheries, and on September 18, 2019 has submitted a Declaration of Voluntary Action to the White Logistics Movement secretariat. The White Logistics Movement aims to address the growing shortage of truck drivers, ensure stable logistics services necessary for daily life and industrial activities, and contribute to economic growth.

The initiatives expressed by Kureha in its Declaration of Voluntary Action are as follows:

- Propose and follow logistics improvements

- Improve shipping facilities

- Use expressways

- Make a modal shift to ship and rail transport

- Draw separate contracts for fares and rates

We will position the White Logistics Movement as part of our CSR activities and work together with Group companies to achieve the initiatives expressed in our Declaration. By promoting these initiatives, we also respond to the regulation by law to limit the annual overtime hours of drivers to 960 hours starting in April 2024 (the "2024 problem").

RC TOPICS: Kureha Construction's Mizuhiro Masaki received the Green Cross Award from the Japan Industrial Safety & Health Association in recognition of his occupational safety and health efforts

On October 19, 2022, Kureha Construction's Mizuhiro Masaki (Vice President, General Manager of Safety and Health Management Department) received the Green Cross Award from the Japan Industrial Safety & Health Association at the 81st National Industrial Safety and Health Convention held at Marine Messe Fukuoka. This award is given to individuals and groups in all industries throughout Japan by the Japan Industrial Safety & Health Association for their outstanding achievements in promoting and improving industrial safety and occupational health over many years.

Vice President Masaki has been engaged in occupational safety and health management intermittently for a total of 34 years, starting as an on-site safety and health manager, and currently serves as the General Manager of the Safety and Health Management Department and General Safety and Health Manager at Kureha Construction. He has also participated in the promotion of local occupational safety and health activities at the Iwaki Labor Standards Association, where he has served as a director and auditor since 2017.

He was recognized for the work that he did during this period, including early proposals and promotion of such now-common practices as work safety checks with the participation of all workers, the use of clearly drawn layout plans for visualization of work steps, on-site patrols by supervisors, improved communication between workers and managers, and more effective health management through promotion of secondary health checkups.

The recognition of his steadfast efforts over many years is a source of pride for the Kureha Group and an encouragement to all employees.

Kureha Group places great importance on thorough management of safety based on our belief of safety first under any circumstances, and we will continue to strive for safety and health management based on this belief.

The 81st National Industrial Safety and Health Convention in Fukuoka

- Sustainability

- Message from the President

- Kureha Group's Sustainability

- Material Issues

- Environmental Report

- Social Report

- Governance Report

- Kureha Group's Sustainable Product Development

- Environmentally and Socially Friendly Products

- GRI Standards Content Index/Comparison with ISO 26000

- ESG Data Collection

- Sustainability Report Archive

- Group Company Initiatives

- External Recognition

- Sustainability Site Editing Policy and Contents of the Report